Do you need help? Here Us: 07971459261

07971459261

Injection Molding Process

Product Details:

X

Injection Molding Process Price And Quantity

- 1 Unit

Injection Molding Process Trade Information

- 7 Days

- Delhi, All India

Product Description

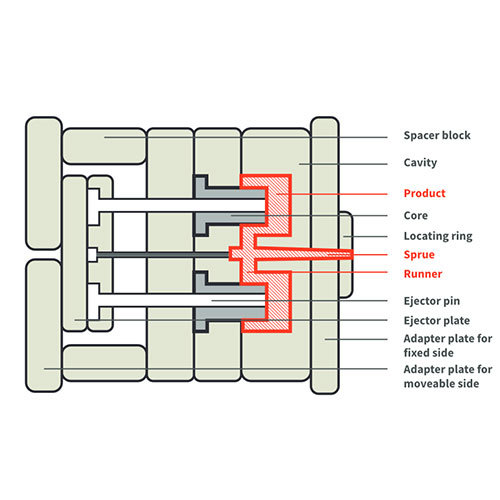

Discover our brilliant Injection Molding Process, a first-rate solution for manufacturing high-quality plastic components. Highlighted by its transcendent precision and adaptable design, it supports both single and multiple cavity molds, with reduced cycle times between 30-60 seconds. The process operates at an injection pressure of 1000-2500 bar and tolerances as low as 0.01 mm. Experience outstanding surface finishes-glossy, matte, or textured-adaptable runner systems, and fully-automated or semi-automatic operation. Promotion includes custom colors and materials, serving industrial, automotive, electronics, and consumer goods sectors with a production capacity of up to 10,000 parts per day across India.

Versatile Usage and Advanced Features

The Injection Molding Process stands out for its adaptability to various application types, including industrial, automotive, electronics, and consumer goods. With options for single or multiple cavities, automatic or manual ejection, and advanced runner systems, it accommodates specific usage needs and product complexities. Capable of handling shot weights from 1 gram to several kilograms, it ensures precise manufacturing. Custom finishes and colors further enhance product appeal, making it an essential tool for manufacturers seeking perfection.

Main Domestic Market and Shipment Details

Primarily serving the Indian domestic market, our Injection Molding Process is offered through convenient payment terms and meticulous packaging, ensuring secure shipped goods. All shipments are tracked for timely arrival, with packaging designed to safeguard molds and finished products during transit. We prioritize client satisfaction, handling every shipment with care and delivering products promptly to your doorstep, thus supporting seamless operations and sustained productivity.

Versatile Usage and Advanced Features

The Injection Molding Process stands out for its adaptability to various application types, including industrial, automotive, electronics, and consumer goods. With options for single or multiple cavities, automatic or manual ejection, and advanced runner systems, it accommodates specific usage needs and product complexities. Capable of handling shot weights from 1 gram to several kilograms, it ensures precise manufacturing. Custom finishes and colors further enhance product appeal, making it an essential tool for manufacturers seeking perfection.

Main Domestic Market and Shipment Details

Primarily serving the Indian domestic market, our Injection Molding Process is offered through convenient payment terms and meticulous packaging, ensuring secure shipped goods. All shipments are tracked for timely arrival, with packaging designed to safeguard molds and finished products during transit. We prioritize client satisfaction, handling every shipment with care and delivering products promptly to your doorstep, thus supporting seamless operations and sustained productivity.

FAQ's of Injection Molding Process:

Q: How does the Injection Molding Process cater to different application sectors?

A: The Injection Molding Process is designed for flexibility, supporting a wide range of applications from industrial and automotive to electronics and consumer goods. Its customizable features and material options make it suitable for complex product requirements.Q: What are the benefits of using reduced cycle times in injection molding?

A: Reduced cycle times lead to faster production rates, allowing manufacturers to produce more parts in less time without compromising quality. This enhances efficiency and lowers operational costs.Q: When can I expect the shipped goods to arrive after placing an order?

A: Shipment timelines typically depend on order size and location, but most shipped goods reach the client within a stipulated period, ensuring timely arrival and minimal delays in your production schedule.Q: Where is the Injection Molding Process service available?

A: The process is readily available throughout India, catering to manufacturers and service providers looking for high-grade injection molding solutions.Q: What specific features highlight the injection molding process?

A: Highlighted features include tolerance levels of 0.01 mm, customizable cavity numbers, hot/cold runner systems, automatic or manual ejection, and glossy, matte, or textured finishes-all contributing to superior, first-rate output quality.Q: How does the automation grade impact the production process?

A: The automation grade, ranging from automatic to semi-automatic, determines the efficiency and ease of operation. Fully-automated systems maximize productivity and consistency, while semi-automatic options provide more control based on specific requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

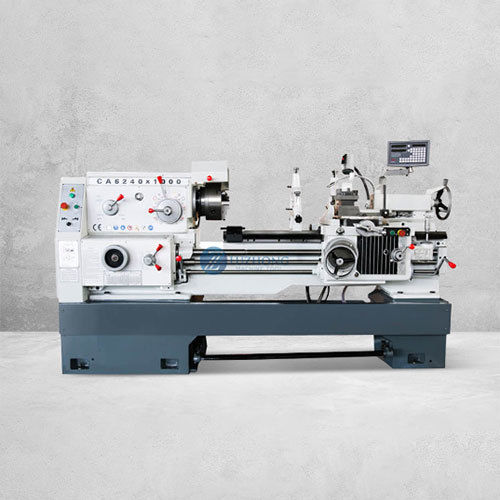

Other Products in 'Tool Manufacturing' category

We are mainly catering to clients in Pan India.

We only work on plastic.

We only work on plastic.

|

AADINATH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |